Introduction

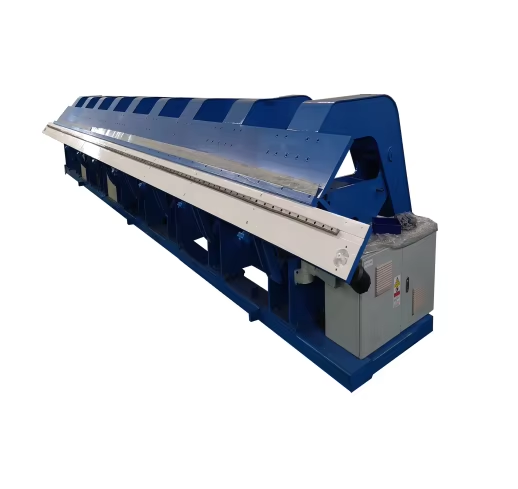

In the metal processing industry, slitting lines and folder equipment are two significant pieces of machinery that play crucial roles in different aspects of production. Slitting lines are dedicated to precisely cutting wide metal coils into narrower strips, while folder equipment is designed for bending metal sheets into desired angles and shapes. Their combined functionality contributes to a wide range of manufacturing processes across various sectors like automotive, construction, and electronics. Xiamen BMS Group is proud to offer top-notch slitting lines and folder equipment, which are engineered with advanced technology and reliable performance to meet the diverse demands of the industry.

Advantages of Slitting Lines

1. Precise Slitting Capability

Equipped with high-precision circular blades and advanced knife shaft adjustment systems, slitting lines can achieve remarkable precision in cutting wide metal coils into narrow strips. The width tolerance can often be maintained within ±0.5mm. This level of accuracy is essential for industries where consistent strip dimensions are crucial, such as in the production of electrical components or precision machinery parts.

2. Wide Range of Material Compatibility

Slitting lines are capable of handling a diverse array of metal materials. Whether it's carbon steel, stainless steel, aluminum alloy, or copper, these machines can adapt. By adjusting parameters like the type of blade material, cutting speed, and tension control, they can effectively process both soft and hard metals, making them applicable in numerous industries including automotive, packaging, and pipe manufacturing.

3. High-Speed and Stable Operation

Powered by robust drive systems and featuring an optimized mechanical structure, slitting lines can operate at high speeds while maintaining excellent stability. They are capable of processing several tons of metal coils per hour, which makes them highly suitable for large-scale production environments. This efficient operation helps manufacturers meet tight production schedules and high-volume demands.

4. High Degree of Automation

From the moment of coil uncoiling to the final recoiling of the slit strips, slitting lines are equipped with intelligent automation control systems. Operators only need to set parameters such as the cutting width, coil thickness, and running speed on the control terminal, and the entire process will proceed automatically. This not only reduces manual intervention, minimizing labor costs, but also decreases the likelihood of human errors that could affect the quality of the slit strips.

5. Precise Tension Control

One of the key features of slitting lines is their precise tension control mechanism. Throughout the slitting process, it can accurately regulate and maintain the tension of the coil at all times. This ensures that the coil remains properly aligned during uncoiling, slitting, and recoiling, preventing issues like strip wandering, reduced cutting accuracy, or surface scratches on the strips, thereby guaranteeing high-quality slitting results.

6. Excellent Reel Quality

The specialized reel device on slitting lines is designed to achieve high-quality winding of the slit narrow strips. Depending on factors such as the width, thickness, and material of the strips, it can automatically adjust parameters like the winding tension and speed. This results in neatly wound and tightly packed coils that are convenient for storage, transportation, and subsequent processing operations.

Advantages of Folder Equipment

1. High-Precision Bending

Folder equipment utilizes precise mold systems and accurate angle and stroke control mechanisms to achieve high-precision bending of metal sheets. Whether it's a simple right-angle bend or a complex multi-angle and multi-curve bend, the bending angle error can be controlled within ±0.5°. This ensures that the bent workpieces meet the exact design requirements, making it highly favored in industries like precision mechanical manufacturing and electronic equipment enclosure production.

2. Multiple Bending Modes

These machines support various bending methods, including free bending and die forming bending. Moreover, some advanced folder equipment comes with an automatic mold changing function, allowing for quick and convenient switching between different bending modes according to the specific requirements of the sheet material, thickness, and the desired shape of the bend. This flexibility enables them to handle a wide variety of processing tasks and meet diverse manufacturing needs.

3. User-Friendly Operation

The operation interface of folder equipment is designed to be simple and intuitive. Operators can easily set parameters such as the bending angle, bending length, and bending speed on the control panel. Additionally, the equipment provides corresponding operation prompts and graphical guidance, enabling even those with relatively less experience to quickly master the operation skills and complete complex bending tasks with ease.

4. Powerful Power and Adjustable Pressure

Equipped with high-power hydraulic or electric drive systems, folder equipment can generate sufficient bending force to handle metal sheets of different thicknesses and materials. Furthermore, it has a pressure adjustment function that allows for precise tuning of the bending pressure based on the specific characteristics of the sheet. This ensures a smooth bending process, avoiding situations where excessive pressure damages the sheet or insufficient pressure leads to poor bending results.

5. Sturdy and Durable Structure

The overall structure of folder equipment is constructed using high-strength steel, with key parts undergoing special heat treatment and reinforcement processes. This gives the equipment strong rigidity and stability. The high-quality molds and transmission components also possess excellent wear and corrosion resistance, enabling them to maintain good performance during long-term and frequent use. As a result, it reduces equipment failures and maintenance costs while extending the service life of the equipment.

6. Comprehensive Safety Protection

Folder equipment is installed with a complete set of safety protection devices, such as protective fences, light curtain protection devices, and emergency stop buttons. The protective fences prevent operators from accidentally coming into contact with the working area during operation. The light curtain protection device can immediately stop the equipment when it detects an object entering the dangerous area. The emergency stop button allows for quick shutdown of the equipment in case of emergencies, ensuring the personal safety of operators and the normal operation of the equipment at all times.

Comparing Slitting Lines and Folder Equipment

1. Function and Purpose

Slitting lines are primarily focused on the transformation of wide metal coils into narrow strips through precise cutting. They are the key equipment in the early stage of material preparation for metal processing. In contrast, folder equipment is centered around bending metal sheets or strips into specific shapes and angles, playing a vital role in the later stage of shaping the final or semi-final products. For example, in the production of automotive parts, slitting lines first process the steel coils into the required narrow strips, which are then sent to the folder equipment for bending into components like brackets or frames.

2. Workflow Integration

In a production line, slitting lines usually act as the starting point, providing precisely cut strips for subsequent processing steps that may involve folder equipment. They ensure a continuous supply of materials with consistent quality in terms of width and other specifications. Folder equipment, on the other hand, relies on the input from slitting lines or other sources of cut sheets to perform its bending operations. The two need to be coordinated in terms of processing speed and material flow to achieve an efficient production process.

3. Performance Emphasis

Slitting lines put a strong emphasis on speed and the consistency of material division. Their tension control systems are crucial for maintaining the uniformity of the slit strips in terms of width and quality. On the other hand, folder equipment is all about precision in angle and shape formation. Its adjustable pressure systems are designed to meet the diverse requirements of different bending tasks, ensuring that each bend is accurate and meets the design standards. While slitting lines are optimized for continuous processing of coils, folder equipment is better suited for batch processing of individual sheets or strips.

4. Application Scenarios

Slitting lines find extensive use in industries that require narrow metal strips, such as electrical component manufacturing, where precise-width copper strips are needed for circuit boards, or in metal packaging where narrow strips are used for sealing and decoration. Folder equipment is commonly employed in sectors where shaped metal parts are essential, like appliance manufacturing for forming the outer casings of refrigerators or washing machines, or in construction hardware for producing brackets and hinges.

In conclusion, both slitting lines and folder equipment are indispensable in the modern metal processing industry. They each have their own unique advantages and play distinct roles in different stages of production. Whether you are aiming for precise coil slitting or accurate metal bending, Xiamen BMS Group's slitting lines and folder equipment can offer reliable performance and high-quality solutions. If you have any questions about which equipment is more suitable for your specific production needs or want to know more details about our products, please don't hesitate to leave us an inquiry. Our team of experts will be happy to assist you in making the best choice for your operations.