1002, בניין הבינלאומי הואלון, מספר 1, דרך גויין, שיאמן, פוג'יאן, סין +86-592-5622236 [email protected] +8613328323529

הדרישה למכונת חיתך קפיצים קומפקטית נובעת מצורך שוק ברור: לא כל עסק שיכולה להפיק תועלת מחיתך פנימי מוצדיק את המקום או הנפח הדרושים לخط אוטומטי גדול. קווי חיתך מסורתיים מעוצבים לייצור בתפוקה גבוהה וчастית תופסים שטח משמעותי באורך וברוחב, ודורשים מרחבים מיוחדים בתוך מתקן. עם זאת, קיים קטע משמעותי בתעשיית עיבדת המתכות – כולל יצרני מותאמים, יצרני רכונות מיוחדים ומרכזי שירות אזוריים – הפועלים בקנה מידה שבו גמישות, שיקולי יעילות ושמירה על שטח מוגבל הם קריטיים יותר מהיכולת לייצר בכמות גדולה. עבור עסקים אלו, קווי חיתך בגודל מלא מייצגים השקעה מוגזמת הן במונחי הון והן בשטח פיזי. המכונת החיתך הקומפקטית של קפיצים ממלאה את הפער הזה באופן מושלם, ופועלת ככלי מדויק ולא כמערכת ייצור מונולית.

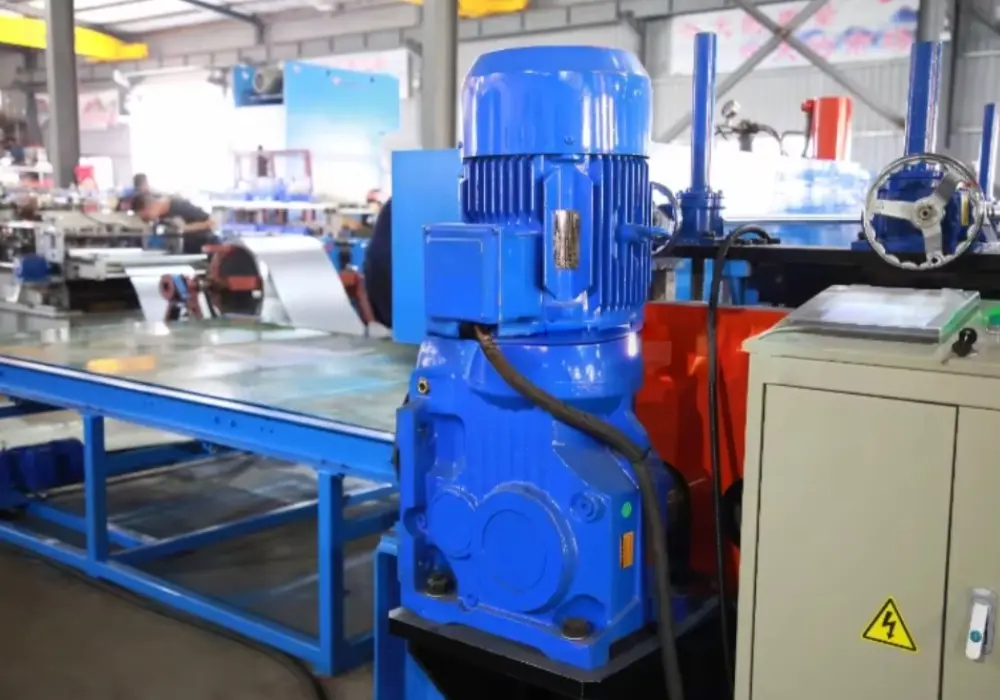

האתגר ההנדסי ביצירת פתרון קומפקטי יעיל נמצא באיחוד עיצוב חכם. זה לא עניין של בניית מכונה 'חלשה יותר', אלא עניין של בניית מכונה 'חכמה יותר'. כל רכיב חייב להיות מותאם אופטימלית מבחינת שטח, מבלי לפגוע בפונקציה הליבה שלו. למשל, מסגרת המכונה עשויה להשתמש בעיצוב אנכי או מרובה שורות כדי לצמצם את השטח הדרוש. המכשירים לפירור והטילול עשויים להשתתף בסיס עבה משותף או לעצב עם רדיוס סיבוב קטן יותר. ראש החיתוך עצמו, גם אם יכיל פחות תחנות סכינים, חייב לשמור על הקשיחות והדיוק הנדרשים לביצוע חיתוכים מדויקים. המטרה היא להסיר את העומס והעומס שאינו חיוני, תוך שמירה על שלמות תהליך החיתוך. זה מחייב הבנה מעמיקה של התכונות שהן 'חובה' להפעלה אמינה, ושל אלה שהן 'רצויות' אך ניתן להתאים או לפשט עבור היישום היעד.

היכולת שלנו לעצב וליצר מגוונות מתקנים איכותיים לדקיקת קפיצים קטנים נובעת מהגישה ההנדסית הגמישה והניסיון הרחב שלנו בייצור. אנו מבינים שפתרון אחד אינו מתאים לכולם. התהלים העיצוב שלנו ליחידות קטנות כולל שיתוף פעולה צמוד עם הלקוחות כדי להבין אילוצרי השטח הספציפיים שלהם, פרופיל החומר והיעדים של תפוקה. בעזרת הרקע הנרחב שלנו בבניית מערכות גדולות ומורכבות יותר, אנו יודעים בדיוק היכן ניתן לזרז התהליך מבלי להקריב ביצועים. מתקני הייצור שלנו מוכנים להתמודד הן עם פרויקטים בקנה מידה גדול והן עם כרכים קטנים ומותאמים אישית, מה שמאפשר לנו לייצר מכונות ממוקדות אלו עם תשומת לב זהה לאיכות הלחמת, דיוק העיבка ואילוצרי ההרכה. זה מבטיח שאפילו המודלים שלנו שמבוססים על שיקולי שטח הם עמידים, אמינים ונבונים להחזיק לאורך זמן. על ידי הצעת מתקן לדקיקת קפיצים קטן, אנו מאפשרים לתחום אוسع של עסקים לשלוט בשרשרת האספקה שלהם, לצמצם זמני מוביל על הזמנות סרטים מותאמים אישית ולשפר הרווחיות על ידי הוספת ערך לקפיצים שנרכשו, הכל בתוך הגבלות של שטחי הפעילות הקיימים שלהם.