1002,Hualun International Mansion,No.1, Guyan Road, Xiamen, Fujian,China +86-592-5622236 [email protected] +8613328323529

The demand for a compact coil slitting machine arises from a clear market need: not every business that could benefit from in-house slitting has the space or volume justification for a sprawling, fully automated line. Traditional slitting lines are designed for high throughput and often occupy significant length and width, requiring dedicated bays within a facility. However, a substantial segment of the metalworking industry—including custom fabricators, specialized component manufacturers, and regional service centers—operates on a scale where agility, flexibility, and efficient use of limited space are more critical than sheer mass production capacity. For these businesses, a full-sized line represents an overinvestment in both capital and real estate. The compact coil slitting machine fills this gap perfectly, acting as a precision tool rather than a monolithic production system.

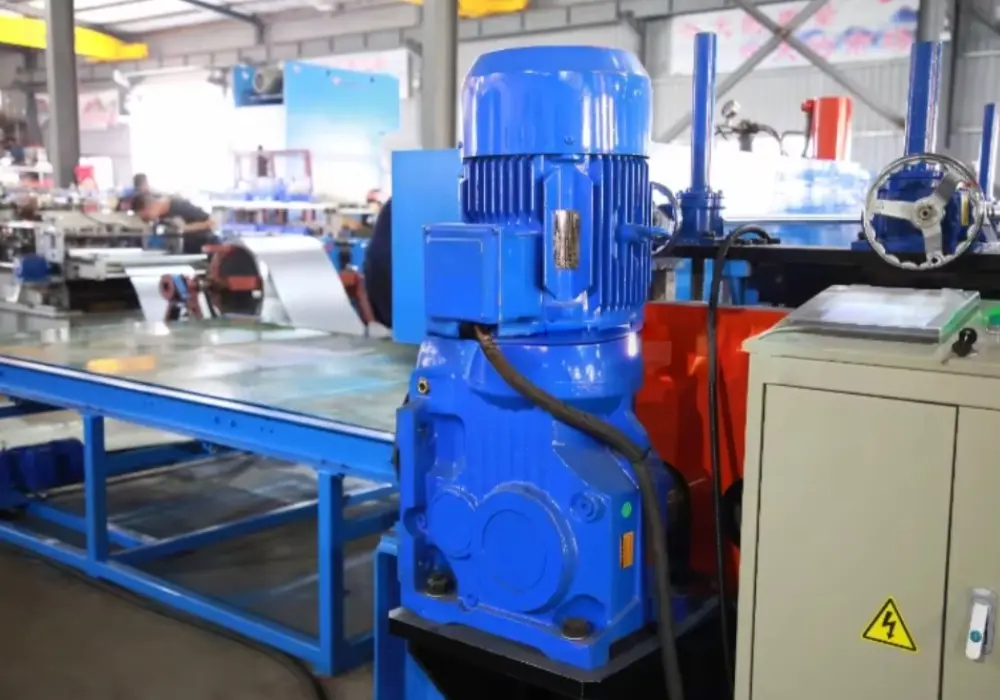

The engineering challenge in creating an effective compact solution lies in intelligent design consolidation. It’s not about building a “weaker” machine, but about building a “smarter” one. Every component must be optimized for space without compromising its core function. For instance, the machine frame might use a more vertical or stacked design to reduce the floor plan. The decoiler and recoiler might share a common robust base or be designed with a smaller turning radius. The slitting head itself, while possibly having fewer knife stations, must retain the rigidity and precision to make accurate cuts. The goal is to strip away non-essential complexity and bulk while preserving the integrity of the slitting process. This requires a deep understanding of which features are “must-haves” for reliable operation and which are “nice-to-haves” that can be adapted or simplified for the target application.

Our ability to design and manufacture high-quality compact coil slitting machine options stems from our flexible engineering approach and broad manufacturing experience. We understand that one size does not fit all. Our design process for compact units involves close collaboration with customers to understand their specific spatial constraints, material profile, and output goals. Leveraging our extensive background in building larger, more complex systems, we know precisely where we can streamline without sacrificing performance. Our manufacturing facilities are equipped to handle both large-scale projects and smaller, customized batches, allowing us to produce these focused machines with the same attention to weld quality, machining accuracy, and assembly standards. This ensures that even our most space-conscious models are durable, reliable, and built to last. By offering a compact coil slitting machine, we empower a wider range of businesses to take control of their supply chain, reduce lead times on custom strip orders, and improve profitability by adding value to purchased coils, all within the confines of their existing operational space.