1002,Hualun International Mansion,No.1, Guyan Road, Xiamen, Fujian,China +86-592-5622236 [email protected] +8613328323529

For serious manufacturers, the selection of core production machinery is a pivotal decision that dictates efficiency, quality ceilings, and long-term viability. Investing in advanced magnetic bending equipment represents a strategic commitment to overcoming the limitations of legacy systems. This technology is particularly transformative for operations where the costs of tooling, surface rework, and production inflexibility erode profitability and constrain business growth.

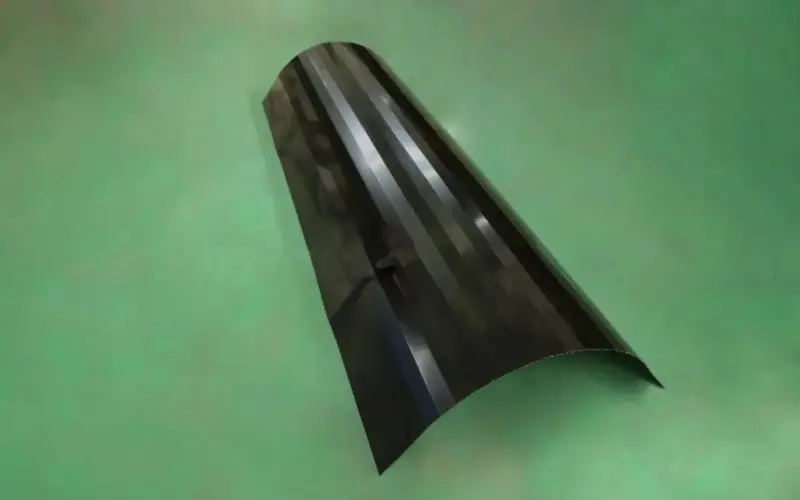

The diverse application landscape for this equipment underscores its versatility. In the HVAC and ductwork manufacturing sector, it enables the rapid production of clean, precise fittings and components without compromising galvanized or coated surfaces, ensuring optimal airflow and longevity. Producers of retail display systems and commercial furniture leverage its ability to create aesthetically perfect, structurally sound frames and panels from various finished metals, enhancing product appeal. Within the agricultural and heavy machinery supply chain, it is used to form durable, high-tolerance parts for equipment where strength and precise fit are critical. Moreover, for specialized component suppliers serving multiple industries, this equipment acts as a versatile profit center, allowing them to efficiently process small to medium batches for different clients with a guaranteed level of quality that builds lasting partnerships.

Our position as a trusted supplier of this sophisticated equipment is anchored in substantial industrial pedigree. As part of a manufacturing group with over a quarter-century of focused experience, our designs are informed by real-world production challenges and a deep understanding of global quality expectations. This is validated by our machinery’s compliance with internationally recognized certification standards, a non-negotiable requirement for selling into regulated markets and to major corporate clients. Our extensive track record of delivering solutions to a global clientele across diverse industries has honed our ability to tailor equipment to specific regional and sectoral needs.

Procuring this technology from our company provides several definitive advantages for your operation. Firstly, you benefit from direct access to manufacturing expertise and value. By controlling the entire production process within our owned facilities, we ensure rigorous quality control while offering competitively priced equipment, delivering exceptional capital value. Secondly, we provide end-to-end global project support. Our established international network, built through decades of exports, is equipped to manage everything from initial technical consultations and logistics to installation support and after-sales service, minimizing your project risk and ensuring a smooth integration into your workflow. Finally, we offer collaborative application development. Our engineering team does not just sell a machine; we partner with your technical staff to analyze your specific materials, desired outputs, and production goals. We can conduct feasibility studies and propose optimized configurations, ensuring the magnetic bending equipment you receive is precisely calibrated to maximize productivity and return on investment within your unique manufacturing context.