1002,Hualun International Mansion,No.1, Guyan Road, Xiamen, Fujian,China +86-592-5622236 [email protected] +8613328323529

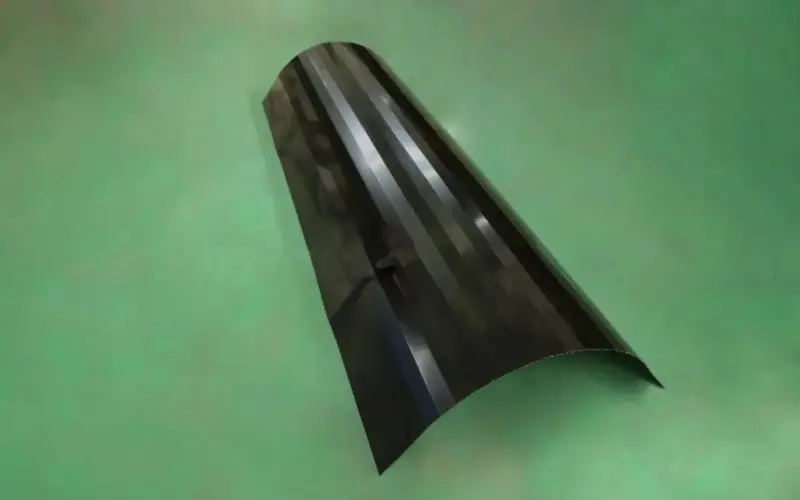

Steel remains the backbone of modern manufacturing and construction, and the process of bending it efficiently and cleanly is a constant focus for fabricators. Traditional press brakes, while powerful, rely on mechanical force that can compromise the surface integrity of valuable pre-finished steel and involve time-consuming setup procedures. A Magnetic Bending Machine for Steel represents a focused technological advancement designed to overcome these specific limitations. By utilizing a controlled electromagnetic field to secure the workpiece, it creates a fundamentally different interaction between the machine and the material. This is not merely an incremental improvement but a shift towards a more intelligent, less invasive forming process that prioritizes both efficiency and the preservation of material quality.

The applications for this technology are central to numerous industries that rely on formed steel components. In architectural metalwork, it enables the flawless bending of cladding panels and trim elements without damaging costly finishes. For electrical enclosure and cabinet manufacturers, it ensures that painted or galvanized sheets remain unmarred throughout fabrication. The HVAC industry benefits from its ability to quickly and cleanly form ductwork components and brackets. In each case, the Magnetic Bending Machine for Steel acts as a critical quality control point, ensuring that the forming step adds functional value without detracting from the material’s inherent or applied properties. This capability is increasingly important as end-users demand higher aesthetic standards and manufacturers seek to minimize waste and rework.

Our company’s development of this industrial-grade solution is informed by our extensive experience in metal forming machinery and a deep understanding of global fabrication challenges. We recognize that for magnetic bending to be viable for steel, the electromagnetic system must be exceptionally robust and reliably controlled. Our engineering focuses on creating magnetic circuits that deliver consistent, high-force output without undesirable thermal effects, ensuring stable performance throughout a production shift. The machine structure is correspondingly overbuilt to handle the reactive forces of bending steel, guaranteeing that precision is maintained. This practical, performance-oriented design philosophy is supported by our integrated manufacturing capabilities, which allow for strict quality control from component sourcing to final assembly. Furthermore, our history of supplying equipment to a worldwide network of industrial clients means we are adept at configuring machines to meet diverse regional standards and operational needs. By choosing our Magnetic Bending Machine for Steel, fabricators are not just acquiring a new piece of equipment; they are investing in a modernized process that enhances their capability to deliver higher-quality steel products with greater efficiency and flexibility.