1002,Hualun International Mansion,No.1, Guyan Road, Xiamen, Fujian,China +86-592-5622236 [email protected] +8613328323529

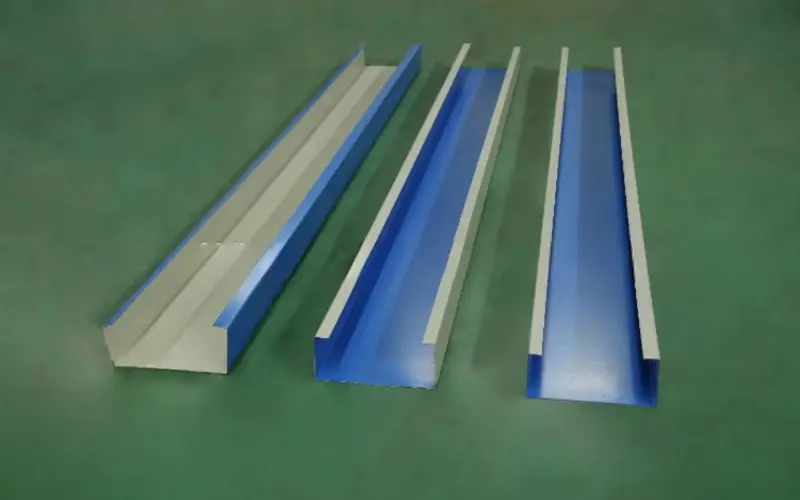

The fabrication of components from thin sheet metal is a discipline defined by its sensitivity to handling and process forces. Materials in the 0.3mm to 1.5mm range, while versatile and cost-effective, lack the structural rigidity of thicker plate. This makes them exceptionally vulnerable to the imperfections introduced by conventional press brakes, where hardened clamp shoes must physically grip the sheet to counteract bending forces. This contact often results in cosmetic damage or subtle deformation that can render a part unusable, especially when visual appeal or precise fit is critical. A dedicated Magnetic Bender for Thin Sheets addresses this fundamental conflict by replacing compressive mechanical force with adhesive magnetic force, creating a holding mechanism that is both immensely strong and entirely non-damaging.

The practical applications for this specialized capability are centered in industries where aesthetics, weight, and precision converge. Manufacturers of high-end consumer electronics utilize these benders to form the internal chassis and external bezels of devices without a single blemish. The architectural metalwork sector employs them to create flawless bends on thin decorative panels and trim. Laboratories and equipment producers form precise housings and brackets for sensitive instruments. In each case, the Magnetic Bender for Thin Sheets acts as a guarantor of quality, ensuring that the forming process adds functional geometry without subtracting from the material's inherent value through surface or structural damage.

Our company’s development of this focused technology leverages our broad expertise in metal forming and our commitment to solving specific industrial challenges. We understand that effective magnetic bending of thin sheets requires more than just a strong magnet; it requires precise control over that force to prevent slippage without over-saturating the material. Our engineering team has developed control algorithms that modulate electromagnetic output in real-time, synchronized with the bending cycle. The machine frame itself is constructed to be exceptionally stiff, as even minor flex can lead to angle inaccuracies that are magnified in thin-material work. This combination of smart control and solid mechanics is what defines our solution. Furthermore, our position as an established manufacturer with a global clientele allows us to incorporate real-world feedback into our designs, ensuring reliability and ease of use. By implementing our Magnetic Bender for Thin Sheets, fabricators can confidently accept orders for high-finish, thin-gauge work, secure in the knowledge that they possess the specialized tooling required to execute it flawlessly, thereby opening new market opportunities and enhancing their reputation for quality.