1002,Hualun International Mansion,No.1, Guyan Road, Xiamen, Fujian,China +86-592-5622236 [email protected] +8613328323529

The AD Double Folder Series takes your sheet metal shop one step closer to automation. Its unique design makes the ARTITECT machine flexible and fast.

|

|

The AD series Double Folder utilizes 50mm drive shafts on both folding beams and upper beam movement. There are a total of 6 drive shafts on the AD series. The drive shaft ensures parallelism of the beams, which is great for forming radius parts and longevity of the machine. Torsion drive shafts remove the ‘twisting’ that can occur over time from hydraulic cylinders fighting each other’s force. Drive shafts allow for faster speeds. All shafts rotate on closed spherical bearings for smooth synchronized movement. No jerky movement of any axis while forming.

|

|

| Syncronized Control Drive Shafts | The 0.1 degree accurate positioning is achieved by applying digital absolute value rotary encoders directly on the torsion shafts. |

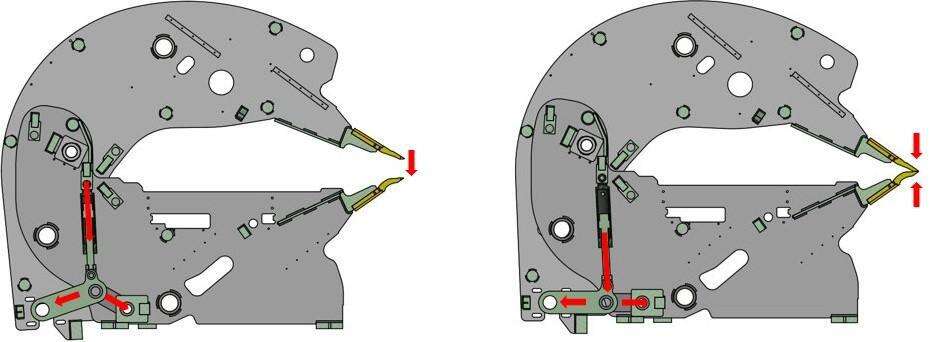

The mechanism on the clamping beam is unique. Unlike systems of other manufacturers, where clamping power is applied to the clamping beam tool by means of hydraulic force, ARTITECT utilizes a toggle mechanism with Zero-Point Locking that ensure the clamping beam tool firmly hold in place the sheet metal. This also ensures no over clamping of the upper beam.

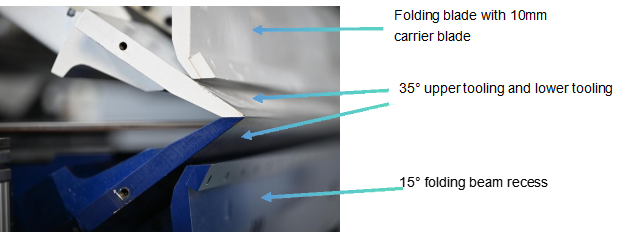

The combined features and geometry of the ARTITECT AD’s workspace makes this machine even more unique and flexible. Each of the benefits listed below are specifically design to benefit a flexible machine for different applications.

Dynamic Folding allows the moving of multiple machine axes at the same time. With this, repositioning and stop times are reduced to a minimum. Thanks to the simultaneous tool movements an extremely fluent and highly dynamic folding process results. All in all features that will lead to a significant increase in productivity and a substantial grow in capacity.

|

HARDENEDLINKAGES The AD Double Folder incorporates hardened linkages and pins on both the upper and lower bending beam. |

|

For more precise forming on various material types, adjustable crowning is standard.

|

Separate drive shaft adjust for material thickness With the fully-automatic radius adjustment system, the clamping tools can be positioned precisely in accordance with the sheet thickness used, therefore achieving perfect folding radii. The material thickness can be defined in the controller. The adjustment value can also be adapted to suit the specific material, in order to enable the folding of larger radii. Adjustment is fully hydraulic. Also great for control of material during hemming process. |

Drive Shaft for Material Thickness |

The hydraulics have been developed and designed specifically for the AD series by ARTITECT. Each axis is controlled by its own, safe servo proportional valve. An additional pressure control valve per system guarantees the low-power pressure less closed-circuit operation. At the same time the pressure for the respective axis is set via the valve. As an additional safety feature, each axis is equipped with two lock poppet valves. They ensure that the axes can be stopped immediately in the event of a power failure or defective proportional valve. Each axis's thus triple-secured.

|

Hydraulic Station |

100% Digital Servo Proportional Valve |

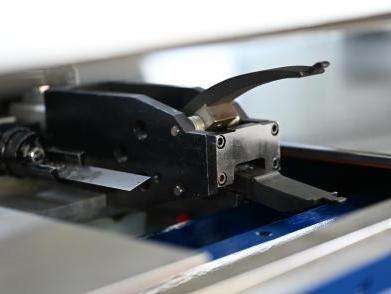

The backgauge gripper system has a range from 20mm - 1250mm at 250mm/ sec. We offer a gripper that can be custom designed to meet the customer’s part requirements. The grippers come standard with clamping from both top and bottom, to insure even clamping of sensitive material. The gripper system is a modular type system, so change over is quick if more than one type of gripper system is purchased. The pneumatic grippers use 6.0 bar of air.

|

|

|

| Dual Grippers | Gripper system with open jaw | Gripper system with closed jaw |

SPRINGFINGERFor big flanges or position less than 12mm. -smallest gauge 5mm -smallest Z shape gauge 10mm -gauge range 5-1150mm |

|

Fully automatic tapered gauge, you can produce offsets of left to right of +/-127mm. Since integrated by the control, allows you to work without a fixed tapered reference point. The software automatically calculates the best position.

EASYFOLDGRAPIC CONTROLEASYFOLD controls 10-axis and manages: type and thickness of materials via library, blank size, backgauge position, bend angle, upper beam open height, angle correction, data table and clamping pressures. Other features are: » Touch-screen profile programming auto folding sequence » Folder with categories and profile catalogue » Automatic, semi-automatic and manual mode » Management for over 10,000 profile variants » Collision simulation program » 3D visualization of the profiles » Input of geometry data » Variable speeds » Computer functions » Status display showing the actual status of the machine controller » 2-channel safety circuits » Reference-point calibration entry » Configuration inputs for control parameters » Data handling via USB or network (LAN/Wi-Fi) » DXF data import and interface » Remote maintenance |

Finger Drawing

Profile Management

Collision Simulation

3D Visualization |

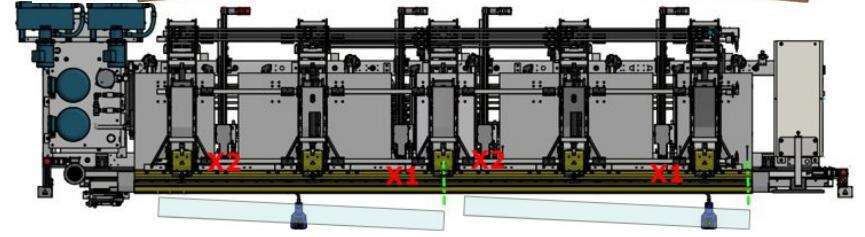

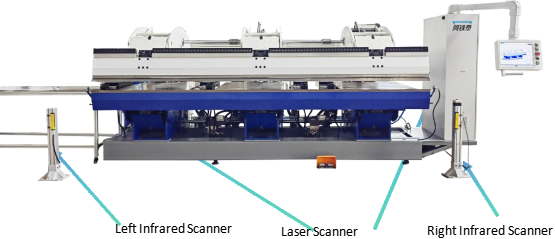

In automatic mode, the operator is protected by the laser scanner. In semi-auto mode and manual mode, infrared scanner doesn’t work. When sheet is put into machine and operator leaves danger area, only after press confirm button, machine will work. Once someone or something enter safety area, the laser scanner will stop the machine immediately.

The laser scanner only works in semi-auto or manual mode. It doesn’t work in auto mode when the infrared scanner works.

The transmitter and receiver of the laser monitoring equipment are fitted to the two columns. If the laser beam is interrupted, the clamp beam stops immediately. The laser recognizes hands, fingers and the like. Below the 15 mm clamp beam stop the laser is disabled.

LED bending lines provide lighting, because seeing well means more security. Helpful in semi-automatic mode.

Allows the handling and processing of long sheets or several parts at the same time with one operator. This doubles productivity and half labor cost. 710mm extension, stainless steel top with multi-layer composite for full load capacity of machine. The tables are servo driven, so fully programmable. The extension is either calculated based on the sheet’s width or manually by the machine operator.

|

|

| RETRACTED | EXTENDED |

AUTOMATICSIDESHEET LOADINGDEVICE(optional)The integrated side sheet metal side loading device sets new standards. Sheet metal will be fed automatically, fast and flexible via a linear guide. The sheet metal feed-in device is capable to load a sheet the capacity of the machine. The table automatically drops down as sheets are loaded. Loader can feed one single sheet or multiples in a sequence e.g. 2 x 3m on a 6.4m machine. The sheet metal drop position can be freely defined in the controllers setting. |

|

Machine flips part for double sided hem or grip other side of part. Range of part 125mm - 635mm without operator assist. Great than 635mm to 1219mm operator does not have to flip, but does need to assist on keeping part on table after release of suction cups.

|

STEP 1 |

STEP 2 |

|

STEP 3 |

STEP 4 |