1002,Hualun International Mansion,No.1, Guyan Road, Xiamen, Fujian,China +86-592-5622236 [email protected] +8613328323529

The integration of a dedicated cut to length line represents a fundamental upgrade in manufacturing capability, shifting material preparation from a potential bottleneck to a source of competitive advantage. This equipment serves as the critical first link in the production chain, where raw coiled steel is efficiently converted into a valuable, ready-to-fabricate component. For production managers and business owners, the performance of this line directly dictates the pace, cost, and quality of all downstream activities. Moving to an automated, integrated line is a strategic commitment to eliminating the variability and hidden expenses of manual methods, thereby building a more scalable, efficient, and profitable operation capable of meeting modern market demands.

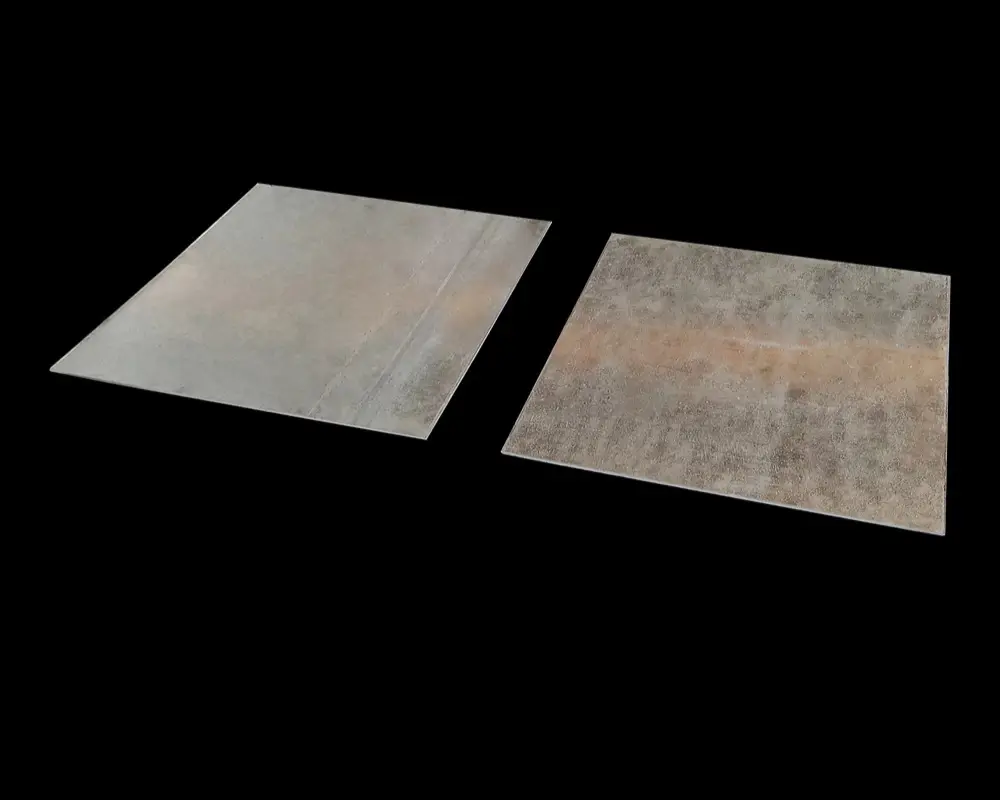

The application scope for a high-performance cut to length line is exceptionally broad, touching nearly every metal-intensive sector. In the construction and architectural industry, these lines are vital for producing accurately sized roof and wall cladding, trim, and structural panels from pre-finished steels, where dimensional consistency is paramount for installation efficiency and aesthetic appeal. Manufacturers of household appliances, electrical enclosures, and HVAC systems rely on them to produce clean, burr-free blanks from galvanized or stainless steel, ensuring seamless fit and finish in final assembly. The automotive and transportation supply chain utilizes these lines to blank critical parts for chassis, frames, and body components, where material conformity is essential for automated welding and assembly processes. Furthermore, for metal service centers and distribution businesses, a reliable cut to length line is the heart of their value-added service model. It allows them to respond agilely to customer demands by processing master coils into specific blank sizes on request. This capability reduces inventory costs for their clients and transforms the service center from a simple supplier into an indispensable processing partner, building long-term customer loyalty and business resilience.

Our expertise in designing and manufacturing this essential industrial equipment is grounded in decades of practical experience and a global operational perspective. With over 25 years of focused development in metal forming and processing technology, our engineering philosophy is informed by real-world application challenges and continuous innovation. This deep-seated knowledge is reflected in machines that are not only robust and precise but also intuitively designed for operator efficiency. Our commitment to meeting rigorous international standards for safety and performance provides our worldwide clientele with critical assurance, particularly for businesses supplying into regulated industries or multinational corporations that mandate certified equipment.

Choosing to source your cut to length line from our company offers several decisive operational benefits. First, you gain from direct manufacturing value and application-focused engineering. As a direct producer with control over our production facilities, we can tailor the machine’s configuration—from the power of the main motor to the diameter of the leveling shafts—to your specific material portfolio and output goals, all while offering the cost advantage of an integrated manufacturer. Second, we provide proven integration support for a seamless startup. Our extensive history of commissioning lines across diverse global markets means we are adept at providing comprehensive documentation, thorough operational training, and responsive technical support, ensuring your new asset is quickly and efficiently integrated into your production flow. Finally, our commitment to durable design and sustained global service safeguards your capital investment. We build for longevity and support our machines with an accessible, responsive system for technical assistance and spare parts, minimizing lifecycle costs and ensuring your line remains a dependable pillar of productivity for years to come.