1002,Hualun International Mansion,No.1, Guyan Road, Xiamen, Fujian,China +86-592-5622236 [email protected] +8613328323529

The decision to integrate a dedicated cut to length line machine into your operation is a strategic move toward industrial efficiency and quality control. This equipment serves as the critical gateway where raw, coiled steel is transformed into a primary, value-added component. For production heads and fabricators, its performance dictates the pace and precision of all subsequent manufacturing stages. Moving beyond manual or semi-automatic methods to a fully integrated line represents a commitment to eliminating variability, reducing hidden costs from waste, and building a scalable production model capable of meeting modern demands for speed and consistency.

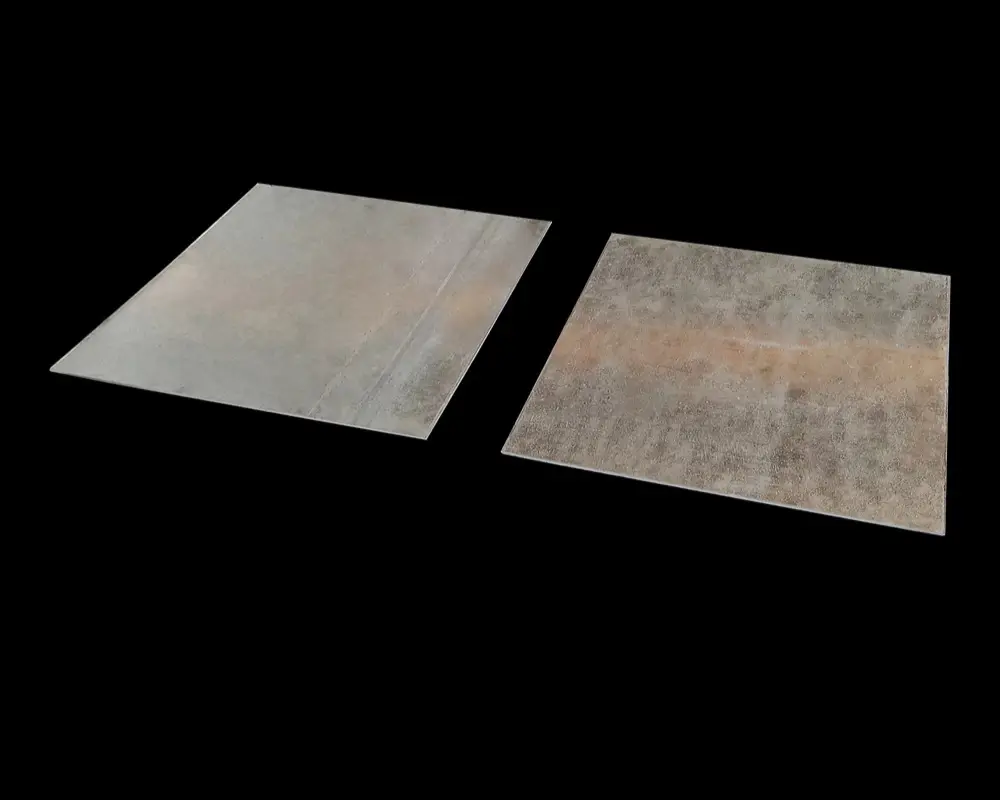

The versatile applications of this essential machine span numerous key industries. In the construction and architectural cladding sector, it is indispensable for producing accurately sized roof and wall panels, trim, and flashing from pre-painted or metallic-coated coils, where dimensional consistency is vital for installation and aesthetics. Manufacturers of electrical enclosures, control cabinets, and HVAC ductwork rely on it to efficiently produce clean, burr-free blanks from galvanized or stainless steel, ensuring seamless assembly. The automotive component and trailer manufacturing industry utilizes these lines to blank parts for chassis, brackets, and body panels, where material conformity is critical for automated welding and assembly lines. Furthermore, for metal service centers and stockists, this cut to length line machine is the core of their value-added service offering. It empowers them to respond quickly to customer demand by processing master coils into specific blank sizes, reducing clients' inventory overhead and solidifying their role as a strategic partner in the supply chain.

Our authority in designing and building this fundamental equipment is rooted in extensive industrial manufacturing experience and a global perspective. With over 25 years of focused development in metal forming and processing technology, our engineering team possesses deep practical knowledge of material behavior, machine dynamics, and production ergonomics. This long-term dedication is validated by our products’ adherence to stringent international certification standards, a crucial assurance for businesses operating in or supplying to regulated global markets and corporate clients who mandate proven equipment safety and performance.

Sourcing your cut to length line machine from our company provides distinct and practical advantages. First, you benefit from direct access to application engineering and competitive value. As a direct manufacturer controlling production in our own facilities, we can tailor the machine’s configuration—from motor power and shaft diameter to control system features—precisely to your material mix and output targets, all while offering the cost efficiency of an integrated producer. Second, we provide proven integration support for seamless startup. Our experience in commissioning lines worldwide equips us to provide comprehensive documentation, thorough operational training, and responsive technical support, ensuring your new asset is integrated smoothly into your workflow and reaches its full productivity potential quickly. Finally, our commitment to durable design and global service protects your investment. We build machines with longevity in mind, using quality components, and support them with an accessible supply chain for spare parts and ongoing technical assistance, minimizing lifecycle costs and ensuring your line remains a reliable engine of productivity for years to come.