1002,Hualun International Mansion,No.1, Guyan Road, Xiamen, Fujian,China +86-592-5622236 [email protected] +8613328323529

Handling coiled steel is the defining challenge at the gateway to countless manufacturing processes. A steel coil tipper is the specialized solution engineered to master this challenge, serving as the critical interface where raw material inventory is converted into productive input. For superintendents and plant engineers, the decision to implement this equipment is a strategic move with far-reaching implications for safety culture, production economics, and asset management. It directly confronts the inefficiencies and hidden costs of manual or improvised steel handling—costs measured in safety incidents, production delays due to feeding problems, and degraded material quality. By standardizing this first step with a mechanized, controlled process, facilities establish a new baseline of predictability. This is essential for competing in markets where consistent quality, on-time delivery, and cost control are paramount, and where the margin for error with expensive steel stock is exceptionally thin.

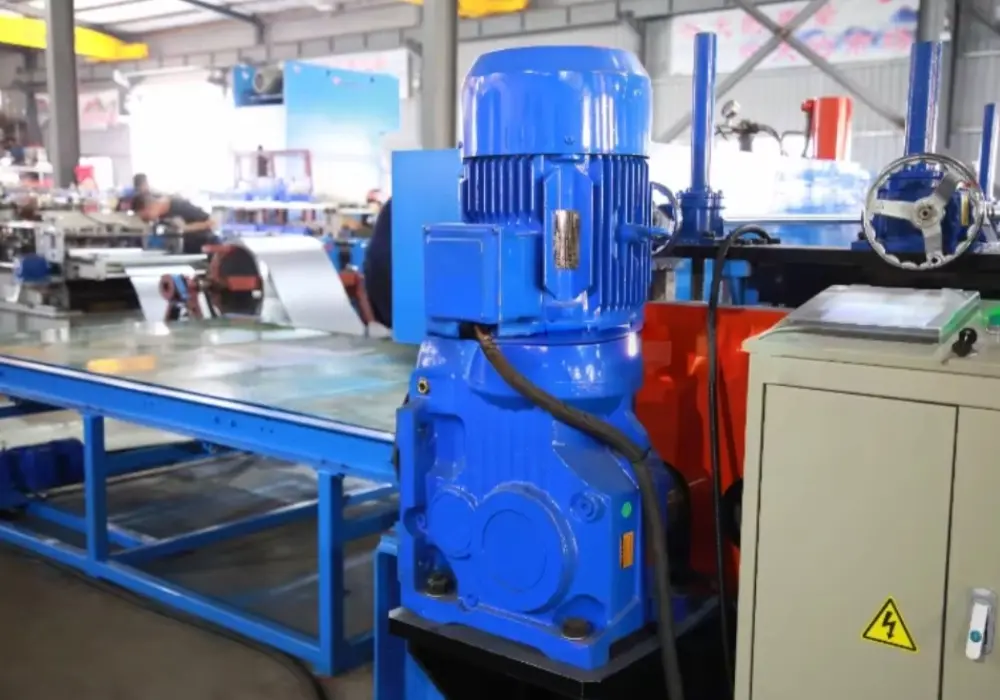

The application of a dedicated steel coil tipper is central to the core of heavy industry. In steel service centers and metal distribution operations, this machine is the workhorse of the receiving and feeding area, enabling the fast, safe turnover of incoming trucks and the efficient supply of multiple cutting or slitting lines. Manufacturers of automotive components, agricultural equipment, and heavy machinery rely on it to feed blanking presses and roll formers with the high-strength steel required for structural parts, where material integrity is non-negotiable. Producers of construction products, such as structural decking, purlins, and framing, depend on its capacity to handle wide, heavy coils for their forming lines. Furthermore, in any facility operating a modern, high-performance processing line, the steel coil tipper is a key enabler of efficiency. It allows for the creation of a semi-automated cell from the point of material intake, minimizing manual labor, reducing handling damage, and ensuring that the sophisticated downstream equipment is fed with the consistency it requires to operate at peak performance, thereby maximizing the return on the entire plant investment.

Our capability to provide this essential industrial solution is grounded in a practical understanding of steel processing and a legacy of manufacturing robust machinery. With over 25 years of focused experience in the metal forming sector, our engineering team possesses deep, applied knowledge of the forces involved in handling dense materials and the operational realities of a busy factory floor. This extensive background ensures our designs are not only strong but also intelligently crafted for real-world usability and maintenance. Our commitment to delivering professional-grade equipment is further demonstrated by adherence to recognized international standards for machinery safety and performance, a fundamental requirement for businesses that operate within global supply chains and are subject to rigorous operational audits.

Choosing our company as your supplier for a steel coil tipper offers distinct and practical benefits. First, you gain from direct, application-focused engineering. We work to understand the specific grades, weights, and dimensions of your steel coils to configure a machine with the appropriate capacity, grip mechanism, and rotation arc. As a direct manufacturer, we control the quality of fabrication and assembly, ensuring the finished product meets our stringent standards for durability, all while offering the value of a direct source. Second, we provide proven expertise in system integration for heavy materials. Our experience ensures the tipper is designed to work in harmony with your material transport systems (like transfer cars or conveyors) and the infeed of your processing equipment, facilitating a smooth, logical, and safe material flow that enhances overall plant logistics. Finally, our established global support framework for industrial assets protects your investment. We provide comprehensive documentation, responsive technical support, and efficient access to genuine spare parts, ensuring your coil tipping equipment maintains the high level of availability and performance that your steel processing schedule depends on, safeguarding your operational continuity and profitability.